Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔧 Engineer your connections like a pro — precision that sparks envy!

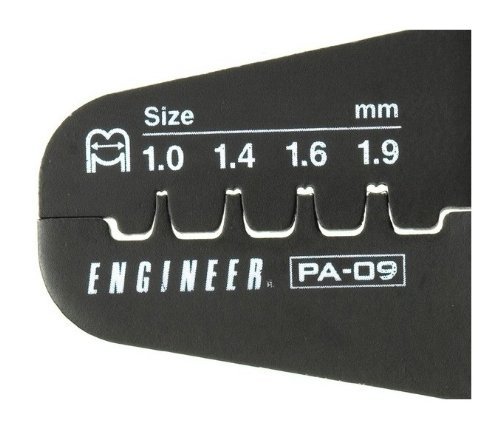

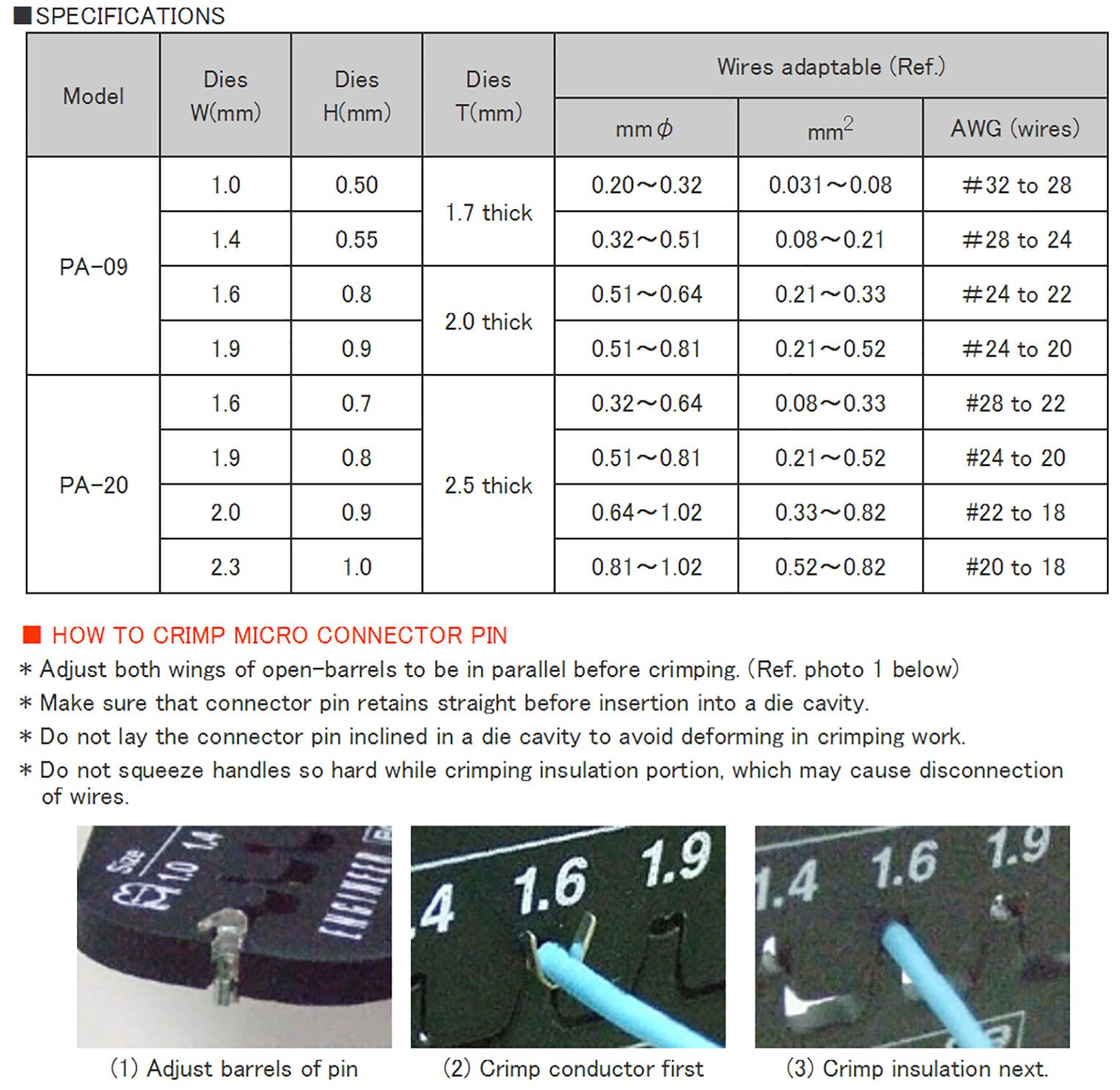

The ENGINEER PA-09 Precision Micro Connector Crimping Pliers deliver unmatched accuracy and durability with 175mm length, four die widths, and Japanese S55C high carbon steel construction. Designed for AWG #32 to #20 wires and over 100 terminal types including MOLEX, JST, and D-Sub connectors, it’s the ultimate tool for professionals and serious hobbyists demanding flawless micro crimps and ergonomic comfort.

| Brand | ENGINEER |

| Color | Orange |

| Grip Type | Ergonomic |

| Handle Material | Thermoplastic Rubber (TPR) |

| Item Weight | 0.14 Kilograms |

| Product Dimensions | 6.89"L x 2.24"W |

J**S

Versatile, Reliable, Feels Good in the Hands. These are the ones you want.

If you are a Hobbyist, buy these. Skip the cheaper ones you can find. These were so good, that I ended up buying a size up, and an extra pair so I always have one in reach. These are a must have whenever I work on my 3d printers, Electronics etc. Pros - High quality and durable - Versatile and compatible with various connector types (JST, Molex, etc) - Precise and consistent crimping results - Comfortable handle / Feel Good to Use - Easy to use - High level of control Cons: - Expensive compared to others - You might need some practice before you master them (due to them being completely manual) - Doesn't work with barrel connectors (IE Spade, etc) that you commonly find at local hardware stores Additional Details: 2 versions of these pliers exist, Taiwan and Japanese made. I've had both in my hands but of different sizes. The Japanese ones are subjectively better, but I wouldn't return the Taiwanese ones. The only major difference is that the Japanese ones have the crimped connectors slide out easier. There are some minor visual differences as well. I mostly view these as a hobbyist tool, if I were using these everyday 9 to 5, I think I might get something else. They are very much a "do it once, do it right, take some more time to do it" type of tool instead of churning out millions of connectors. Though I'm unaware of anything better, these are just so dang good.

P**E

Reliable, reproducible crimps. Worth the money.

I used to think crimping was a waste of time and money, especially since companies like Molex charge $Texas for "proper" crimpers. As a result I would normally solder terminals onto the ends of my wires, and sort of bend what was left with some needle-nose pliers to make it fit into the connector body. Then I did a couple projects where I spec'd PicoBlade connectors. These things are pretty diabolical and soldering them basically rendered them useless because they are so small, and the solder basically wicked everywhere you don't want it. Finally desperate enough, I decided to try the PA-09. It's well-built. Solid, no play in the joint, and does not shift or deform at all while you are doing the crimp. The grip is also solid. I would probably not want to do 100+ crimps in one sitting with this thing, but I can't imagine wanting to do that with any crimper. The docs are brief but effective. You want the sides of the connector to be parallel when you place it into the tool. If it's not, you picked the wrong size, and you will get bad results. I think I managed to destroy one PicoBlade terminal and after that I was producing perfectly serviceable crimps. I've gone on to crimp other terminals as well and it's unlikely I will go back to soldering them. One thing I would mention, and feel silly for not realizing at first. Normally you have to make two crimps to put a terminal on the end of a wire. One for the actual conductor, and another which crimps into the insulation as kind of a strain relief. I made the mistake of trying to use a larger size for the insulation crimp. They are the same size. It makes sense when you think about it, but of course I did not think about it.

J**Z

Excellent one and it’s Made in Japan

This made in Japan version is an authentic Engineer precision PA-09. Please Don’t be full by the Made in Taiwan version. My first order on Amazon was fulfilled by one of the sellers from Japan, but it was made in Taiwan, so I immediately know this was fake and return it. Thus, I reached out to another seller based in the United States and it was confirmed he had Made In Japan version which is true authentic. ( why? When you buy it from other parts stores, it’s all made in Japan) The tool is excellent to crimp all kind of connectors, after I received it today, I had already crimped 20 JST-XH connectors without any issue.

J**E

Excellent wire crimps for a wide array of terminals and wire sizes

Let me start by saying that these Engineer PA-20 Universal Wire Crimps are the best you can find on Amazon for under $50. They beat the generic blue handled crimp tools and many of the ratcheting crimp tools. It took me some time to decide on the PA-20's but I wish I would have purchased them first over the other two tools that I tried out. The Engineer PA-20 is well built and seems like it will last a long time if used properly for its intended purpose. I like that the crimp tool has a plier-like nose so you can manually shape terminals to hold wires in before accomplishing the crimp. The 4 size options will cover most of my needs working with smaller automotive connectors. The die is shaped and sized accurately so that the terminals don't bend or get crushed when performing the crimp. I tend to use the size up for my initial crimp and then the exact size to finish off the crimp and I always achieve great results with that method. Overall, the Engineer PA-20 is a great precise tool that I will get lots of good use out of. I will be looking to their other selection of tools for future projects. Previously, I had purchased and used this linked ratcheting crimp tool. It made a complete mess of the terminals I was working with even though it was rated for 22 gauge wire and terminals. Also, the ratchet didn't release until you completed a full crimp which often times resulted in too much force being applied. All in all I found I prefer the manual crimp tool over the ratcheting crimp tools since you can control force and accuracy. IWISS SN-48B Non-Insulated Tabs and Receptacles Crimping Plier AWG26-16 0.14-1.5mm²

J**.

Solid Crimpers

Used these to crimp SXH-001T-P0.6 connectors (22–28 AWG) for a 6S FPV battery. Worked well.

M**R

Made crimping very small connectors a bit easier. Breaks it into two steps though.

These crimpers are a bit expensive in my opinion but they came very highly recommended. They are made in Japan and are well known. I searched for them by name because someone I trust told me they were the best. I don't mind spending a bit more to get high quality tools but at first glance, they didn't seem very special to me. They are light. The grips are very fancy but nothing too special. They do work really well so I do not regret the purchase. They make good reliable and verifiable crimps. (more on the verifiable part later) I have only used them on Molex Micro-fit so far but I plan to use them for JST and other connectors in the future. They do not ratchet like some less expensive crimpers but for small connectors the ratcheting is not needed. (maybe not even good) With the ratcheting crimpers I could destroy a plug and not even feel it. With these you get more of a feel for what you are doing. (you feel it when you destroy a connector or when you get it work perfectly) You can over crimp a connector with these and I don't think you can do that with the ratcheting crimpers. You can actually see what you are doing with these. They are so thin you can look from both sides. You crimp the wire and insulation separately unlike the big thick ratcheting crimpers that do both at the same time. I start with the stripped electrical wire crimp first. I close the wings of the terminal just a little with the end of the tool, then insert it into the appropriate groove with the wings facing the bottom of the groove. I squeeze the crimper very carefully to get the wings in the right spot. (so it bottoms out in the groove) Then I put the wire in the right spot between the connector and the grove, holding it tight against the connector and squeeze to crimp. It rolls the wings up on both sides and looks like a factory connection if everything goes well. I check that connection since it is the most important one and them move onto crimping the insulation. I tug on them a bit and if it falls out I start over. I crimped a dozen or more connectors worth of crimps with it so far. (and more to come) I had so much trouble crimping small connectors in the past that I dreaded doing it again. (with the cheap ratcheting crimpers) Those ratcheting crimpers are ok but you can't see much, you can't feel anything and my failure rate was pretty high. Even if I was successful, the wires would fall out randomly. These didn't exactly make it easy but my success rate went way up as did my confidence in the actual connectors. That was the most important thing to me, to get good crimps and have solid wiring on my project. (no wires falling out) I guess the biggest thing is that these have very small grooves and the thickness of the crimper varies based on the size of the groove. I found that matching the thickness of the tool with the area to be crimped was more important than the width of the groove. Because of this, I use the end of the tool which works a bit like a needlenose pliers, to squeeze the wings in just a bit. Then I fit it in the groove that I select. (not based on the width of the groove) You don't want a larger groove if you are going to crimp part of the connector that you didn't want to. When I first got the tool, I picked a groove based on the opening of the groove. That didn't work well because the tool was too thick there and crimped by insulation wings or the connector itself. Making the wings of the connector fit the groove with the proper thickness works much better. (just my opinion) Ok so there are several steps that didn't exist with the ratcheting crimper now that I think about it. After I crimp I had to pull the connector out of the tool. (it was stuck in the groove) Not a very automated process but a verifiable and repeatable multistep process instead. (with a higher success rate though) I really do like being able to pull on the wire after I crimped it. That is the reason to buy this tool. You can't do that with the ratcheting crimper and at times when I crimped with the ratcheting crimpers, the only thing holding the wire in place was the crimp on the insulation!!! Those were failed crimps but they weren't always obvious. This two step process avoids that issue and you can test the crimp on the wire before proceeding to the insulation. You can still mess up the second crimp but you know the first one was good either way. Again I squeeze the wings in a bit to get them started. In summary, the tool is expensive. It feels ok but doesn't feel like a $40 crimper until you use it a bunch. (even then seems a little overpriced) I know there are knockoffs but my friend told me to get this one and that it would make my life easier and my crimps more reliable. I watched some videos and decided to get this brand instead of a knock off. Crimping tiny connectors is a pain. (if you don't do it often that is) This tool seems to make crimps more reliable once you figure it out. Verifying the crimp on the wire alone is very valuable!! I still dread the idea of crimping tiny little connectors but I have more confidence now because I have a better tool.

J**U

Don't waste time with bad crimpers

I tried two other crimpers before these. 1st a generic ratcheting kind and then iCrimp or Iwiss 2820M. The ratcheting ones were way too bulky to crimp any small connectors like JST-XH or PH. The 2820M has about the same form as PA-09; however the jaws were out of alignment upon delivery. After wasting an hour, two dozen connectors and lopping off over 1ft on a cable I wanted cut to size, I still couldn't reliably get a good crimp. The Engineer PA-09, while twice the cost of the 2820M produced 4 perfect crimps back to back out of the box. Seriously, if you value your time at all, just spend the $40 or so to get decent crimpers from the start. The PA-09 feels like a reasonably quality hand tool. Has decent grips, clear markings, feels good to use. The OEM tool for JST connectors is like thousands of $$. Just get these for any hobby or low production use.

M**K

High Quality Crimpers for Small Connectors

If you've ever had the misfortune to crimp any number of small (<2mm) pitch connectors with a pair of needle nose pliers, you know how painful that can be. While I have never used the "official" crimpers from JST or MOLEX (>$400), these crimpers are a dream to use compared to trying to do JST-PH or ZH connectors with needle nose. They are not some cheap stamped steel affair, but precision ground tools, that feel great in your hand and do the electrical and insulation crimps perfectly every time. While there are other, cheaper crimpers out there, these are the only reasonably priced ones i've found that go down to 1mm, which is essential if you want to crimp the smallest JST connectors (most bottom out around 1.6mm). My only compliant is that the connectors sometimes get a little stuck in the tool and require a little wiggling to remove them from the jaws, not a big deal, but a little annoying, especially when you're working with thin wires that have a tendency to break. So far, I have used these with JST-XH, PH, and ZH connectors and they work perfectly. If you're working with these connectors with any regularity, I highly recommend that you buy these crimpers and save yourself a lot of frustration,

Trustpilot

1 day ago

2 weeks ago